Everybody has their own tastes and preferences, and the world we live in constantly caters to that. Most things we consume are the product of some kind of customisation, from the salad dressing we choose to put on our lunch to the phone case that protects our mobile devices. Therefore it has become norm for companies to tailor their products to fit in with this growing customisation demand and offer individual products. But for there to be customisation in mass production industries, a new approach is needed.

Thus, the concept of mass-customisation is born. Joseph Pine defines mass customisation as the mass production of individually customised goods and services. Seems paradoxical, but traditional mass production systems cannot satisfy both consumers and producers, so a mass customisation system is implemented to satisfy both, providing a low-cost customised product.

So how can the fashion industry adapt to this trend?

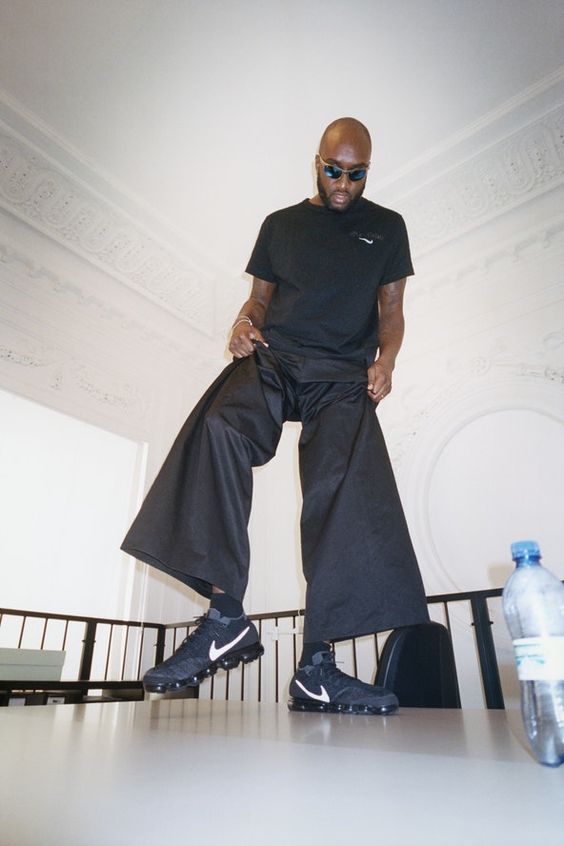

Courtesy of news.com.au

Courtesy of news.com.au

Mass customisation in fashion brings with it several risks, including cost, speed, brand identity loss, and return policies. Since manufacturers only produce a small number of items, they pass that cost onto the consumer rather than absorbing the additional costs. Customisation also takes time, but this is less of a problem when producing high volume of the same custom product. Additionally, custom products from high-end luxury brands jeopardise the brand’s heritage and creative vision and run the risk of losing brand identity. Returning customised products is another topic of debate, because a product tailored to a specific customer would be hard to re-sell to other individuals.

Making products separately also means sacrificing economies of scale. There’s also the challenge of creating a customisation interface for consumers that is enjoyable and easy to use. Companies may also overwhelm customers by offering too many choices, due to the phenomenon of paradox of choice. “Customers don’t want choice,” said Pine. “They just want exactly what they want.”

But maybe the biggest obstacle is the mindset of the consumers. Most customers are used to buying off racks and purchasing items on sale, so this shift might not appeal to everyone.

Courtesy of NikeID

Courtesy of NikeID

Despite all the risks and hardships of the system, mass-customisation is still widely being called the future of fashion. Especially for the new generation of consumers, customisation is a key selling point and entails a clear competitive advantage. Since consumers pay for products before they are put into production, the risk of excess inventory and resulting discounts are eliminated. This leads to a major benefit for businesses in a trend-driven sector like fashion where demand is difficult to predict.

Mass customisation also has a big impact on the way designers work. Alun-Jones states, “Designers are now starting to set style guides rather than finished pieces. So that’s the provocation for designers: what are the key things for your brand and what are the things you’re willing to let go of?”

An example of mass-customisation attempts by luxury fashion brands is Burberry Bespoke. Launched in 2012, it is a personalised service where customers can use the internet to create their own trench coats, offering more than 12 million potential designs. Even those that can’t afford the trench, which has prices that range between $1,800 and $8,800, shared their creations on social media, thus extending the reach of the programme. The company also offers a scarf bar, adding to it’s customisable variety.

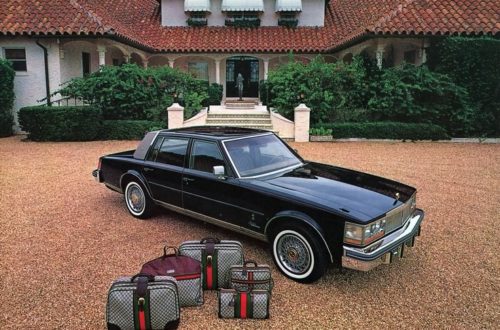

Courtesy of Pursuitist

Courtesy of Pursuitist

There are many other successful examples to be given of mass customisation in the fashion industry including companies like Nike and Levi’s, and they are obviously the ones that took the risks and became one of the pioneers of the so called future of fashion. With the demand for this kind of applications constantly growing, more and more companies are bound to follow suit. The future of fashion therefore seems to be a very customisable one for sure.

by Selin Hatunoglu